Differential Dynamic Scale Loop

H200/H400

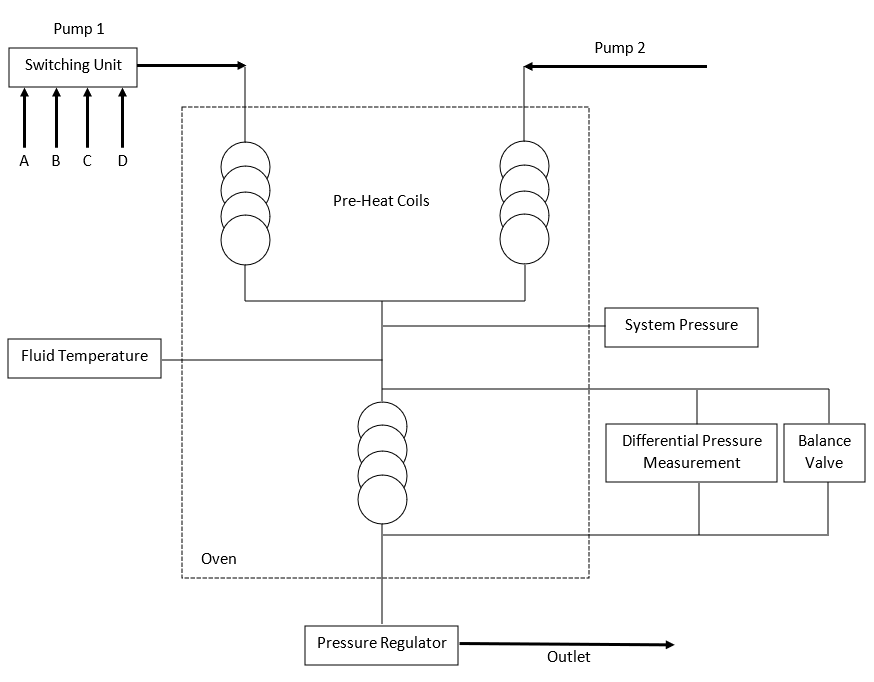

The Dynamic (Differential) scale loop is a tube blocking system for the evaluation of scale inhibitors. The basic principle involves mixing two incompatible brines in a narrow bore test coil. Scale begins to form in the coil creating a differential pressure. The time taken for this formation gives an indication of inhibitor performance.

01. Temperature & Pressure

Techbox Systems manufacture units to suit all temperature and pressure requirements.

02. The numbers

Our standard test rigs are the H200 (200 Bar, 2900 psi) and H400 (400 Bar, 5800

psi) units. Both operate at up to 250°C (482°F).

03. Manufacture & Design

We specialise in designing and manufacturing bespoke equipment to meet

customer’s specific requirements.

Oven Internal

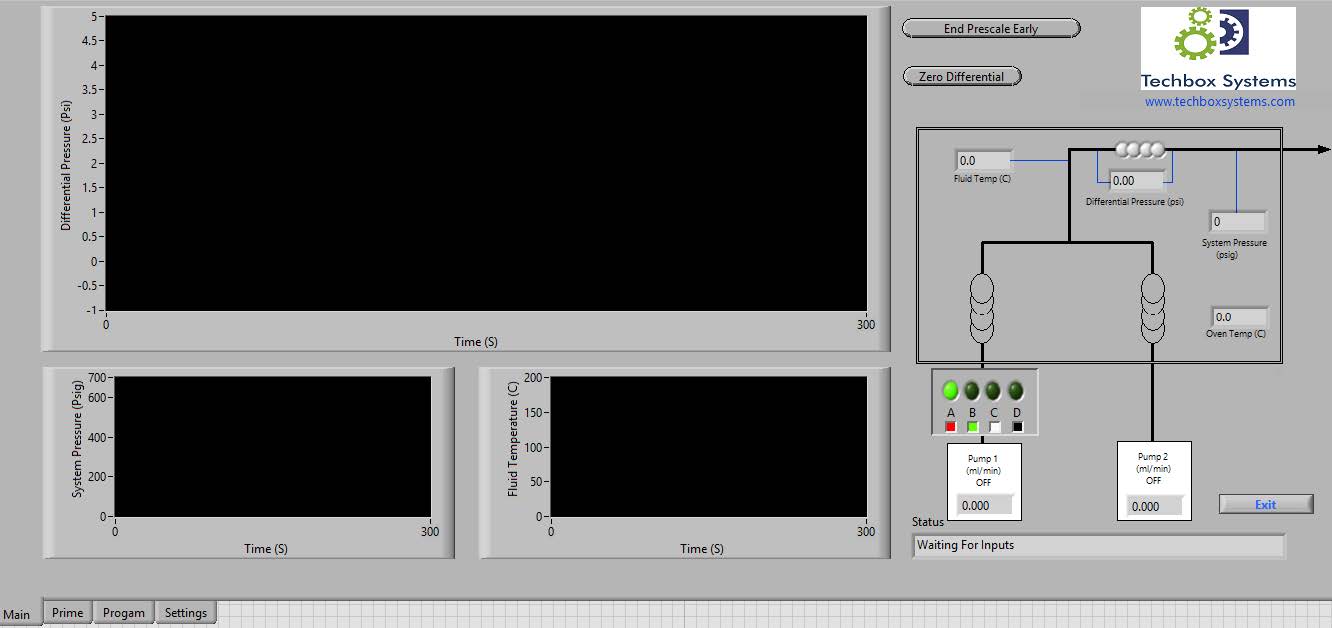

The computer controlled fan assisted oven contains two pre-heat coils in addition to the test coil. Fluid temperature is monitored and recorded prior to entering the test coil. The oven temperature is also recorded. Oven temperature can be changed programmatically during the test.

HPLC Pumps

Quality, German built Knauer pumps are used with twin pistons to ensure smooth flow. Pumps have built in pressure transducers with priming port. The pressure transducers provide an additional layer of safety to stop the pumps should the pressure increase above the maximum permissible.

Heat exchanger, balance valve & Differential transducer

Our units offer a heat exchanger with forced air cooling on the outlet. This ensures that even when testing at 250°C the waste fluid has cooled to a safe level before leaving the machine. The differential transducer, balance valve and back pressure valve are all located on the right of the rig with easy access for maintenance.

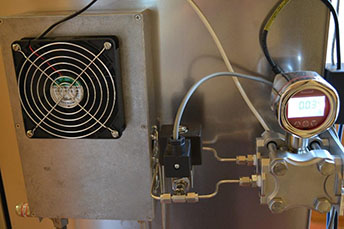

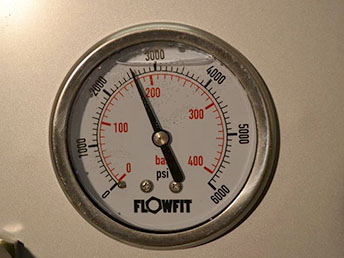

Front Panel Gauge

For safety, our rigs incorporate a gauge on the front panel as a quick indication of pressure in the system. This is in addition to two over pressure PRV’s.

Peristaltic Pump

A peristaltic pump is used to circulate water around the back of the pump heads. This flushes the piston rods preventing premature damage to the seals.

Techbox H200 & H400 DSL Software (Main screen)

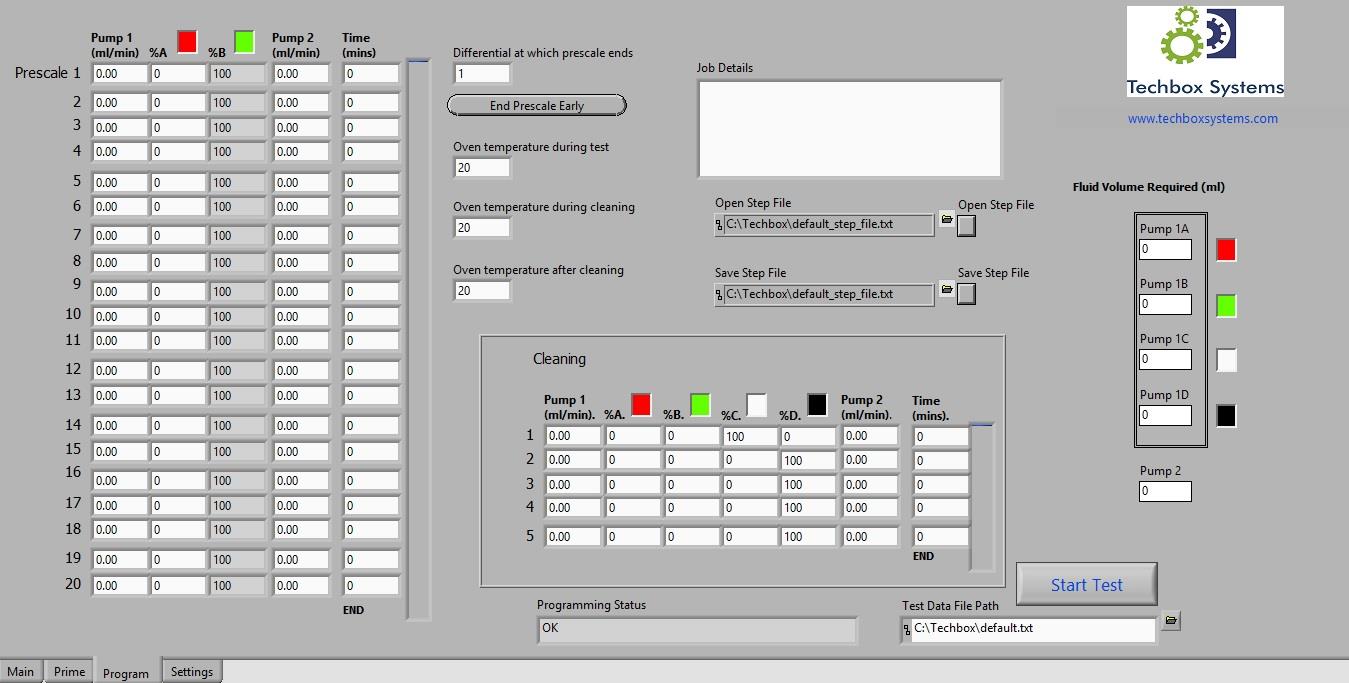

Techbox H200 & H400 DSL Software (Program screen)

The programming screen enables up to 20 dilutions to be programmed. The program varies the amount of fluid passing into pump 1 through the switching unit. This enables the concentration of inhibitor to be varied in steps. The inhibitor concentration is gradually reduced over the 20 steps until scale starts to form in the test coil. This is indicated by an increase in differential pressure. At this point the cleaning process starts. Normally, this would comprise de-scaler followed by deionised water. Up to 5 cleaning steps are available.

|

|

Model

|

|

|---|---|---|

|

|

H200

|

H400

|

|

Max Pressure

|

200 Bar (2900 psi)

|

400 Bar (5800 psi)

|

|

Fan Assisted Oven

|

S

|

S

|

|

Cooling Bath

|

O

|

O

|

|

Max Temperature

|

250°C (482°F)

|

250°C (482°F)

|

|

Automatic Testing

|

S

|

S

|

|

High Pressure

|

S

|

S

|

|

Pump Type

|

HPLC

|

HPLC

|

|

Exchangeable Test Coil

|

S

|

S

|

|

High Accuracy Differential Transducer

|

S

|

S

|

|

Piston Flushing

|

S

|

S

|

|

Pressures Displayed & Logged

|

S

|

S

|

|

Temperature Displayed & Logged

|

S

|

S

|

|

Safety Pressure Relief

|

S

|

S

|

|

System Pressure Control

|

S

|

S

|

|

PH Measurement

|

O

|

O

|

|

EC Measurement

|

O

|

O

|

S-Standard O-Option

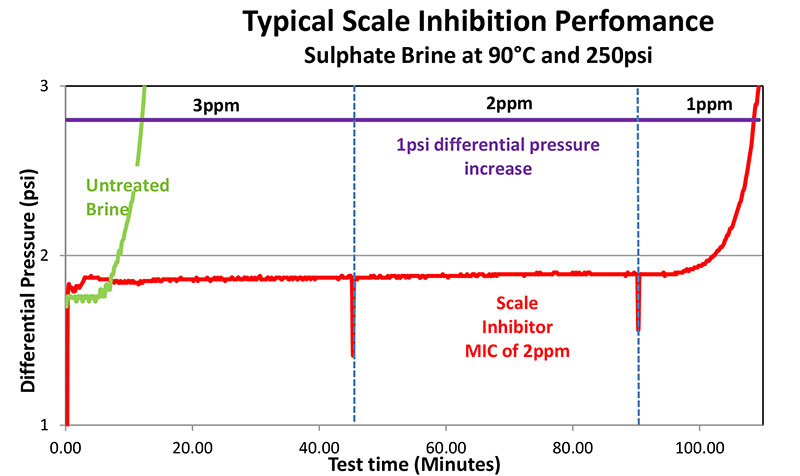

The above graph show typical results. The untreated brine forms scale and starts to block the test coil after about 12 minutes (Blank). The test is then repeated with scale inhibitor present, firstly at 3ppm, automatically reducing to 2ppm after 45 minutes and finally reducing to 1ppm after 90 minutes. At about 110 minutes the test coil starts to block again indicating insufficient inhibitor. At this point the unit automatically cleans itself.

Specifications

- Standard range of systems covering pressures 0 – 400 bar (5800 psi) (Higher on request).

- High accuracy differential pressure measurement.

- Fluid temperature monitoring and recording.

- Oven temperature monitoring and recording

- Fully automated enabling a series of tests to be run with decreasing inhibitor concentrations until the minimum ppm is found.

- Automated cleaning system.

- Flow rate of 0-10ml/min per pump (20ml/min total)

- Replaceable test coil.

- Different length test coils available.

- Available as 110V or 240V.

- Standard test temperatures up to 250°C (482°F).

- Latest, user-friendly windows-based Techbox software.

- Overnight testing possible.

- Small sample volumes.

- Data saved in Excel compatible format.

- Supports two cleaning fluids as standard

- 4 port PEEK switching unit

- Test settings can be saved and reloaded for easily repeatable tests.

- Back pressure valve supplied with interchangeable springs covering typical pressure ranges.

- Supplied with PC pre-loaded with control software.

Other options available on request including:

- Low temperature option

- High pressure option

- Manual version

- Monel tubing available for heated areas.

- Filter

- PH reading on the outlet

- EC reading on the outlet

Download Brochure

Differential Dynamic Scale Loop H200/H400

Address

Aspen Lodge, Braemar Road, Ballater

Call Us

+44 (0)1339 755856

Email Us

sales@techboxsystems.com